Thermal Spray Technology

Metal, Ceramic and Ceramic-Metal High Performance Coatings for Machine Parts and Other Components

Our Services

Renovations and Repairs of Damaged Surfaces

We offer our help with repairing operationally worn or damaged machine components and parts.

Innovations of Surfaces for New Machine Components

We provide support and cooperation to manufacturers of new machine parts by improving the performance of their products with high quality coatings.

Application of Surface Protective Coating Layers

We offer application of advanced protective layers of aluminium, zinc, Zinacor, stainless steel or non-ferrous metals such as copper, bronze, brass and more.

Thermal spraying refers to the technological procedure whereby a suitable source of heat is used to transform a material into either a molten, fused or plastic state. The particles of which are subsequently propelled by an appropriate method towards the prepared surface of the substrate material, i.e. the component, where it then forms a continuous coating with the desired properties.

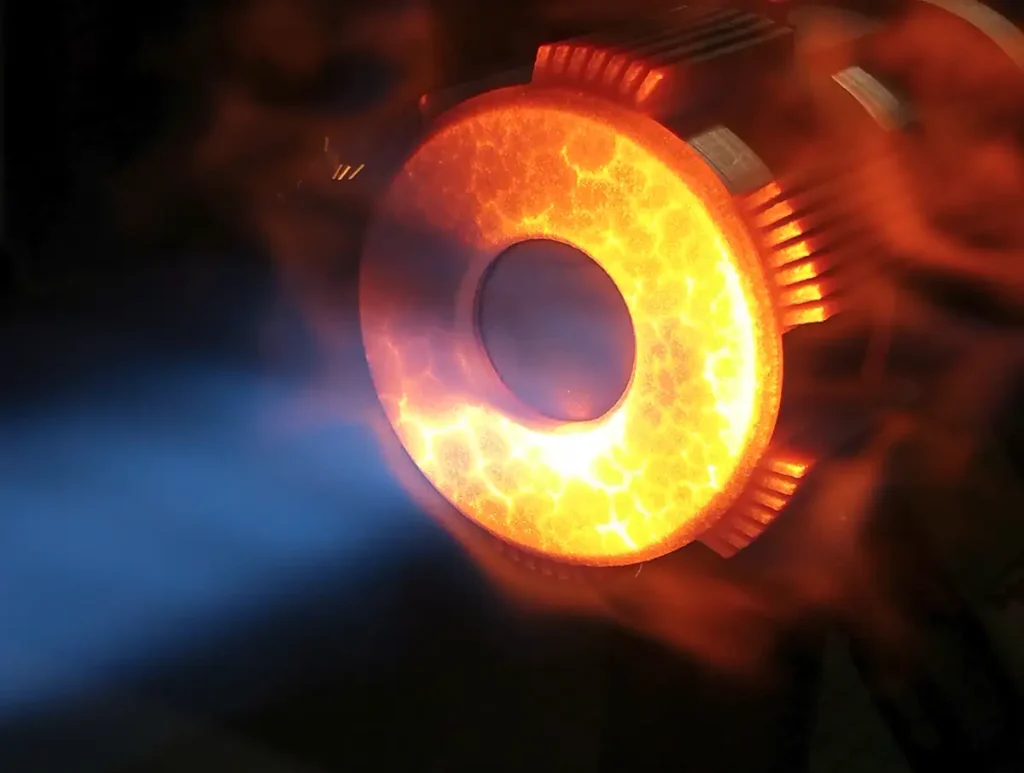

There are several types of plasma spraying. We use the Air Plasma Spraying (APS) technique. The nozzle of the burner consists of a tungsten cathode and copper anode.

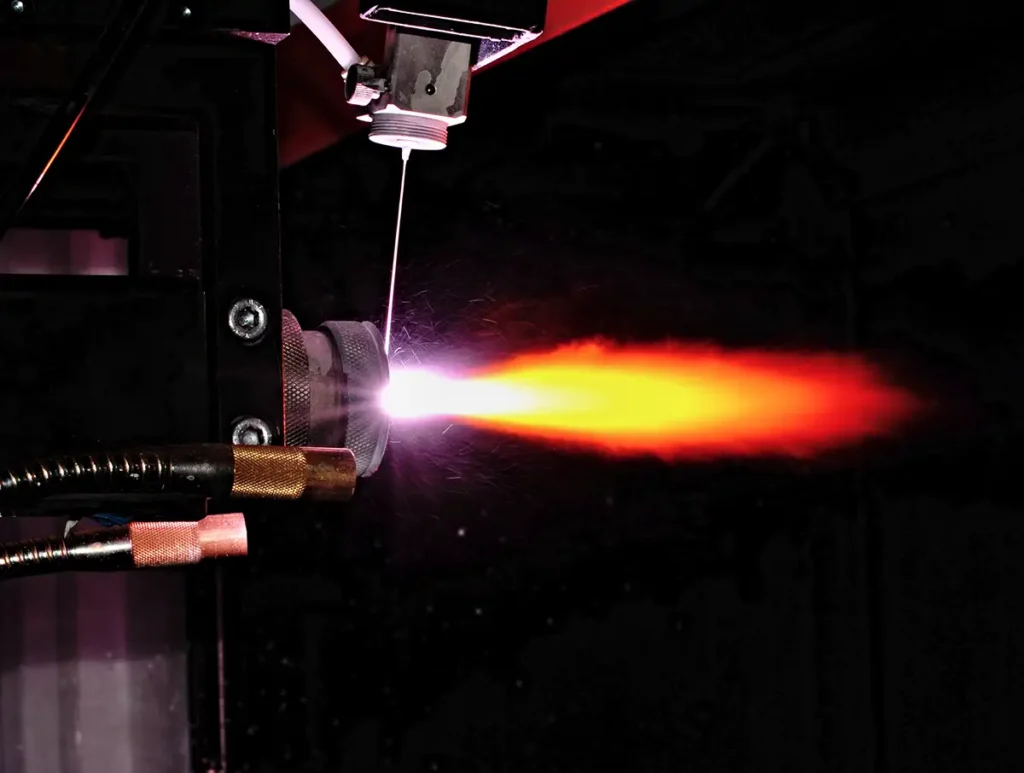

An electric arc burns between two metallic wires, which produces molten particles of material. These particles are propelled by compressed air towards the surface that requires coating.

A mixture of oxygen and kerosene (HVOF liquid fuel), oxygen and propane/ethylene (HVOF gas fuel), or oxygen and a propane–propylene or propane-natural gas mix (HVAF) burns continuously

The material in the form of wire or powder enters the ignited mixed gas (oxy-acetylene, propane-butane, propylene) where it is propelled towards the surface, substrate material which is being coated.

What we can help with

Workpiece Repairs

Wire Drawing Drum Repairs

Bushing Repairs

Bearing Repairs

Rotor Shaft Repairs

Bronze Coatings

Screw Conveyors

Sealing Surfaces Repairs

Surface Treatment

Piston Rod Repairs

Corrosion Protection

And much more

Quality Control

The process automation eliminates even the slightest possibility of human error. In 2014, we opened a robotized workshop with a monitoring and recording system that ensures superior coating results. We use Accura by Tecnar technology, allowing us to check the parameters during the actual process of coating in real time. We are able to monitor basic information of the coated particles such as temperature or speed. This exact parameter setting and particle quality control ensures a high quality of the coating and serves in repetitive production.

High-Quality Materials

We use a wide range of high-quality coating materials from global producers in the form of wire or powder. We are equipped with mixing and sieving system for various powders of required fraction. As a result, we are able to create and apply highly specific, tailor-made coatings.

Applicable Dimensions for Coating

Our technological equipment allows us to apply coatings to machine parts up to:

- Max. diameter of 1,500 mm

- Max. length of 11,000 mm

- Max. weight of 10,000 kg

Applicable Dimensions for Further Machining

We are quipped with a machining center and tools, allowing us to work with coatings up to:

- Max. diameter of 1,500 mm

- Max. length of 11,000 mm

- Max. weight of 2,000 kg

Our Customers

Industry

Industry

Industry